Container/apparatus engineering

Ausgewiesenes Know-how

Ludwig Elkuch AG has proven expertise in container and apparatus engineering. Our customers value our versatility in solutions from various industries as well as our specific knowledge on a case-by-case basis.

We build containers for mineral oil storage, solvent tanks, pressure vessels for air, gases and liquids.

In addition, chrome steel containers for the chemical industry, containers for cleaning systems and special containers for industrial processes.

In addition, we supply apparatuses for chemical and thermal engineering, reaction vessels, stirring and mixing vessels with heating and cooling coils or cooling jackets, rectification columns, autoclaves with quick-release fasteners for pressure and vacuum operations, shell-and-tube heat exchangers, chimneys, flue gas pipes, scrubbers, filter vessels, gasometers.

Decisive for the quality level

Elkuch is approved by the SQS for welding objects of the material qualities boiler plates and fine-grained steels and for stainless steels. We also work with the "Notified Body", such as Swiss Safety Enter, Germanisch Lloyd, TÜV Nord/Süd etc., on a project-related basis. Quality assurance is carried out by qualified welding specialists (welding engineer/welding expert). The quality assurance system is based on ISO 9001:2015, including ISO 3834-2.

Quality assurance

Investment protection

High availability and trouble-free operation throughout the entire service life is the justified expectation for every new system.

We do our part for this by consistently designing and manufacturing all storage tanks and containers according to the rules of technology (corrosion surcharges, material tolerances, utilization coefficients and optimal material selection), thereby ensuring the protection of your investment.

Every container, whether storage, pressure vessel or gas tank, is designed, constructed, manufactured and tested at Elkuch with the same required care.

Quality

We are certified in several areas and are audited several times a year. The periodic, successful audits also confirm to our customers that we deliver products of consistent, reproducible quality. Thanks to these high quality standards, we were the first manufacturer to supply three hydrogen tanks for use in Switzerland.

Quality inspection

The "Quality Inspection" department, which is independent of production, relies on experienced, expert employees with many years of service in the company. In the areas of non-destructive testing, all necessary tests (X-ray, ultrasonic and magnetic particle testing) can be taken care of by our own personnel. This increases flexibility and allows spot checks to be carried out at any time.

Certificates

Energy Storage

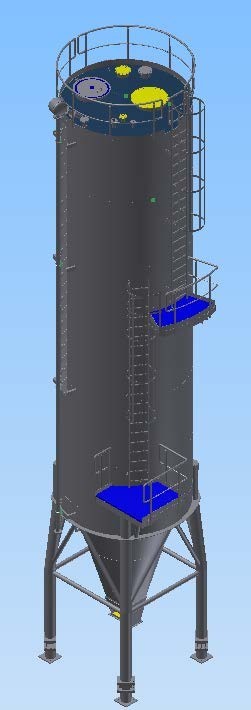

Silo Contruction

Silos individually manufactured according to your wishes and delivered ready to use.