Fibre Cement is an extraordinary building material

Fibre cement, in the early days better known as asbestos cement, started its triumphal procession in 1900. The founder of the Eternit factory in Vöcklabruck, Ludwig Hatschek, discovered at the end of the 19th century the development of a completely new building material that should revolutionize the world.

Fibre cement is a composite material made of cement and tight connection fibres, known as well as Eternit. In the past for the fibre mostly asbestos was used. But meanwhile this dangerous material has been replaced by other fibres like glas-, CFK- or cellulose, at least in Europe. Fibre cement is mainly used in form of plates but as well for tubes and moulds. This building material is extremely resistant and has a multiplicity of advantages compared with other building materials and proves so impressively its worldwide success. It is light, impact resistant and shatter-proof, fire-proof, weather-proof, corrosion-proof and decomposition-proof.

Fibre cement is used as raw product for the manufacturing of small, medium and large format fibre cement plates. The plates are available in different colours and as well with granulated and structured surfaces. Fibre cement that replaced the erstwhile asbestos manufactures is especially used for roof covering and for panelling. For that the soft fibre cement mush is pressed in dedicated moulds. After hardening the products have a very high tensile strength and resistance to bending.

Fibre cement has multiple characteristics:

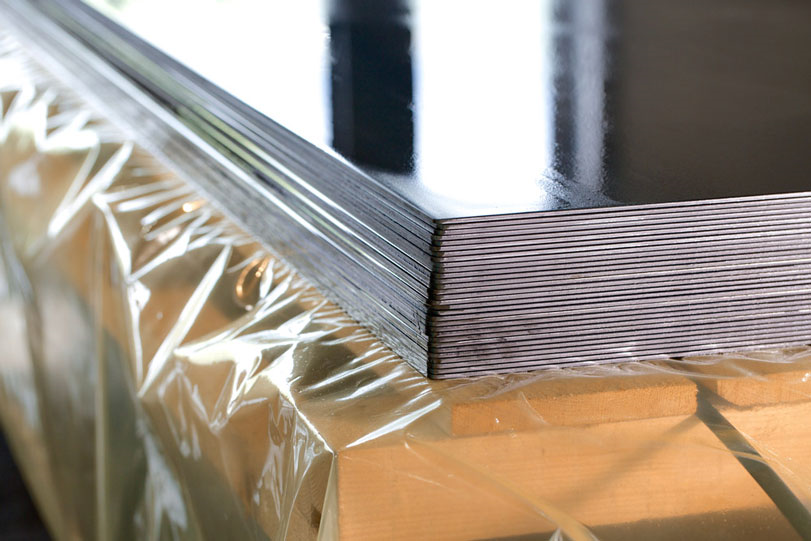

High quality steel templates

High quality steel templates produced with a modern cut-to-length line. A surface without scratches and no tensions in the templates provide a long lifetime.

Steel Grades

The SYRO flat steel moulds are available in hot rolled carbon steel, stainless steel or galvanized steel:

Black Hot Rolled Steel (blued surface)Tensile StrengthYield Strength (min)Elongation (min)

SYRO 5000SYRO 5000520-670 N/mm2>17%

Stainless SteelTensile StrengthYield Strength (min)Elongation (min)

SYRO 7000>520 N/mm2>320 N/mm2>18%

SYRO 7000 S>560-700 N/mm2>420 N/mm2>15%

Electro-plated SteelTensile StrengthYield Strength (min)Elongation (min)

S 350 GDZ 450 MACO*420-570 N/mm2>350 N/mm2>16%

*available Zinc layer thickness with MB surface are Z275=275 g/m3, Z350=350 g/m3 or Z450=450 g/m3

Production Process

The production process for the SYRO flat steel moulds includes:

Product Quality

In order to guarantee the top quality of the SYRO steel moulds

Rounded corners

The SYRO flat steel moulds are made of European steel and are produced in Switzerland and Liechtenstein.

SYRO flat steel moulds are especially dedicated to fibre cement and CBPB manufacturers.

The SYRO flat steel moulds are available in the following dimensions with standard tolerances. Tolerances, which differ from the standard ones must be requested

| Dimensoions | Measurements | Standard Tolerances |

|---|---|---|

|

Length |

max 6'500 mm |

+3.0/-0.0mm |

| Width | max 1'750 mm |

+3.0/-0.0mm |

| Thickness | max 4 mm |

+/-0.2mm |

| Parallelism | 2.0 mm | |

| Flatness | 1.0 mm / 1m |

Robot

The SYRO corrugated steel moulds are made of European steel and are produced in Switzerland and Liechtenstein.

Steel Grades

The SYRO corrugated steel moulds are available in hot rolled carbon steel and galvanized steel:

Black Hot Rolled Steel (blued surface)Tensile StrengthYield Strength (min)Elongation (min)

SYRO 5000SYRO 5000520-670 N/mm2>17%

Electro-plated SteelTensile StrengthYield Strength (min)Elongation (min)

S 350 GDZ 450 MACO*420-570 N/mm2>350 N/mm2>16%

*available Zinc layer thickness with MB surface are Z275=275 g/m3, Z350=350 g/m3 or Z450=450 g/m3

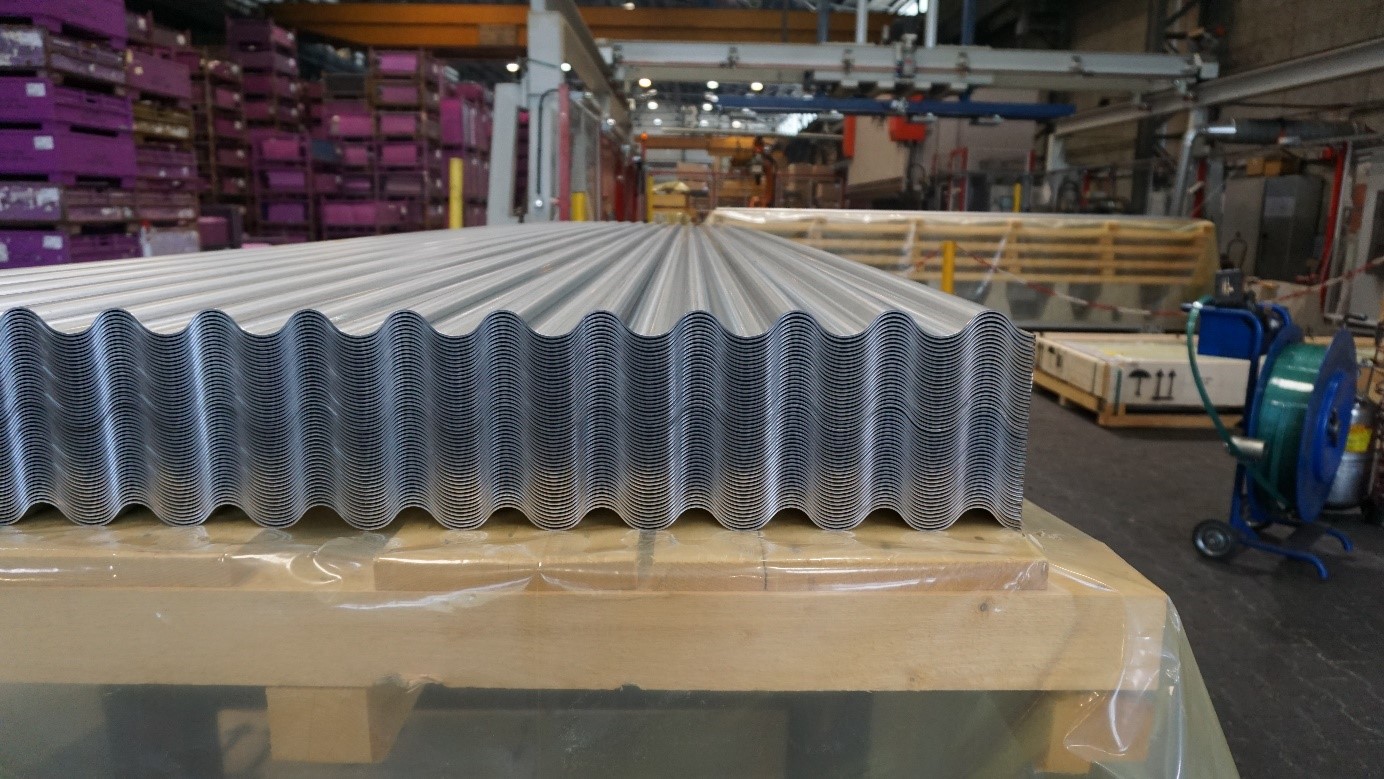

Highly precise corrugated steel moulds

SYRO corrugated steel moulds are especially dedicated to fibre cement manufacturers.

Tolerances

The SYRO corrugated steel moulds are available in the following dimensions with standard tolerances. Tolerances different to the standard ones must be requested.

| Dimensions | Dimension values | Standard Tolerances |

|---|---|---|

| Length | max 6'5000 mm | +3.0/-0.0 mm |

| Width | max 1'750 mm | +2.0/-3.0 mm |

| Thickness | max 2.5mm | +/-0.2 mm |

| Pitch Height | +1.0/-0.5 mm | |

| Pitch Distance | +4.0/-0.8 mm | |

| Total Corrugation | +1.0/-2.5 mm |

Large templates

Our corrugated templates are manufactured so precisely that they can be welded using our modern welding robot to achieve lengths over 7 m.

The SYRO corrugated steel moulds are made of European steel and are produced in Liechtenstein and Switzerland.

Application

SYRO corrugated steel moulds are especially dedicated to fibre cement manufacturers.

Tolerances

The SYRO corrugated steel moulds are available in the following dimensions with standard tolerances. Tolerances different to the standard ones must be requested.

| Dimensions | Dimensions values | Standard Tolerances |

|---|---|---|

| Length | max 6'500 mm | +3.0/-0.0 mm |

| Width | max 1'7500 mm | +2.0/-3.0 mm |

| Thickness | max 2.5 mm | +/-0.2 mm |

| Pitch Height | +1.0/-0.5 mm | |

| Pitch Distance | +4.0/-0.8 mm | |

| Total Corrugation | +1.0/-2.5 mm |

Steel Grades

The SYRO corrugated steel moulds are available in hot rolled carbon steel and galvanized steel:

| Black Hot Rolled Steel (blued surface) | Tensile Strength | Yield Strength (min) | Elongation (min) |

|---|---|---|---|

| SYRO 5000 | SYRO 5000 | >420 N/mm2 | >17% |

| Electro-plated Steel | Tensile Strength | Yield Strength (min) | Elongation (min) |

|---|---|---|---|

| S 350 GDZ 450 MACO* | 420-570 N/mm2 | >350 N/mm2 | >16% |

*available Zinc layer thickness with MB surface are Z275=275 g/m3, Z350=350 g/m3 or Z450=450 g/m3

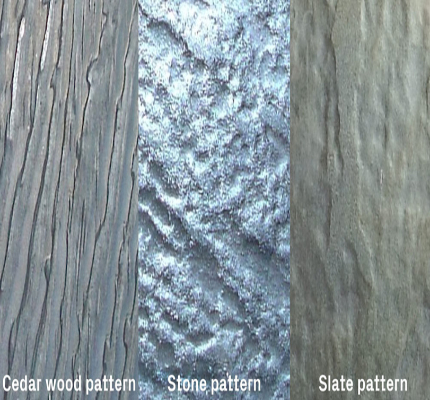

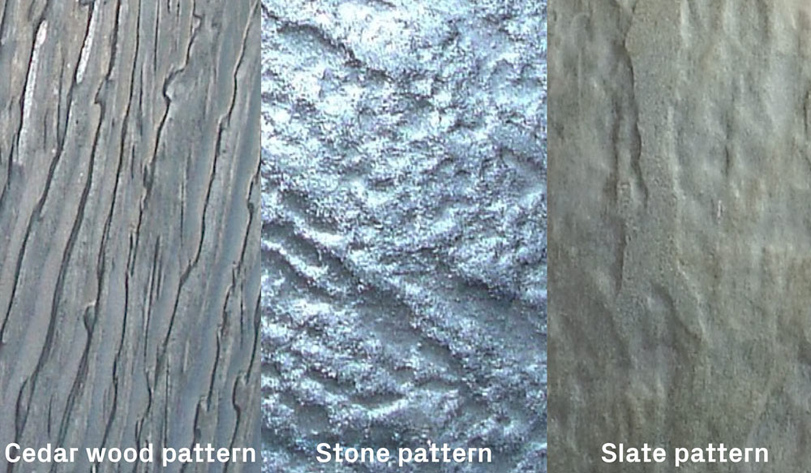

Structured Steel templates in 3 different patterns available.

Extremely durable structured templates for the production of structured FC boards

Structured Steel Moulds with Cedar Wood Pattern

The latest state-of-the-art pattern on a flat steel mould. Never ever the production of structured wood sidings and plates was so economical and with such a high quality. Check it out and convince yourself.

The SYRO flat steel moulds with cedar wood pattern is the latest development of SYRO and is a world novelty that will set new standards to the fibre cement industry. Made of carbon steel SYRO 3000 this SYRO steel mould with cedar wood pattern is much more robust and long-lasting than comparable products made of fibre glass. Inspired by our customers SYRO developed this solution in order to help its customers to optimize their quality and to save costs.

Application

SYRO flat steel moulds with cedar wood pattern are especially dedicated to fibre cement manufacturers, which are using a press.

Advantages of SYRO Steel Moulds compared to common Resin Fibre Glass mould

| Technical Specifications | Mechanical Values |

|---|---|

| Yield Strength ReH | 235 N/mm2 |

| Tensile Strength Rm | 360-510 N/mm2 |

| Elongation A80 | 17% |

| Structure depth | ~ 1mm |

Structured Steel Moulds with Stone Pattern

These steel templates are exclusively available at Elkuch. You get better quality for less money. The structured steel moulds are much more robust than the plastic forms and lasting for a very long time.

Description

The SYRO structured steel moulds are made of European steel and are produced in Northern Europe. At the moment two different stone pattern are available.

Application

SYRO structured steel moulds are especially dedicated to fibre cement and CBPB manufacturers.

Tolerances

The SYRO structured steel moulds are available in the following dimensions with standard tolerances. Tolerances different to the standard ones must be requested.

| Dimensions | Dimensions values | Standard Tolerances |

|---|---|---|

| Length | max 6'500 mm | +3.0/-0.0 mm |

| Width | max 1'750 mm | +3.0/-0.0 mm |

| Thickness | max 4.5 mm | +0.2/-0.2 mm |

| Parallelism | 2.0 mm | |

| Embossing Depth |

≤1.0 mm |

New Product Line

Syro structured polymere templates is our new product line to give FC producers more design freedom at lower investment costs. From one single master mould, which can be produced at our CNC milling center with a very high degree of design freedom, thousands of templates can be produced.